Aluminum Castings Company Can Be Fun For Everyone

Table of ContentsThe 10-Second Trick For Aluminum Castings CompanyAluminum Castings Company - The Facts8 Simple Techniques For Aluminum Castings CompanyRumored Buzz on Aluminum Castings CompanyGetting The Aluminum Castings Company To WorkMore About Aluminum Castings CompanyHow Aluminum Castings Company can Save You Time, Stress, and Money.

The enhancement of silicon can improve the fluidness of the alloy and minimize thermal shrinkage, making the spreading simpler to fill up the mold and lowering the generation of pores. Generally utilized in automobile engine components, hydraulic components, cyndrical tube heads, etc. Light weight aluminum copper alloy (Al-Cu) Consists of aluminum and copper, sometimes with percentages of nickel and manganese included.Blowing up light weight aluminum parts These optional surfaces offer convenience and performance, allowing suppliers to personalize the appearance and performance of light weight aluminum components to specific requirements and applications. Certainly, the actors light weight aluminum itself can likewise be done without surface therapy. You can review this post to find out more concerning metal surface therapies: "15 Types Of Sheet Metal Parts Finishing Options." Tipping right into day-to-day life, we often come across cast aluminum parts.

Everything about Aluminum Castings Company

Each instance showcases the versatility and functionality of cast aluminum in daily life. This write-up provides information concerning actors aluminum, from the spreading process to contrasts with cast iron and functioned aluminum, its benefits, typical basic materials, optional finishes, and numerous cast aluminum manufacturing items. Whether you are checking out prototyping options for a new product or intend to put an existing item into manufacturing, please call us and we have professional engineers to help you.

Indicators on Aluminum Castings Company You Need To Know

- Cast light weight aluminum items might have interior defects such as pores and incorporations, which impact their stamina and performance.

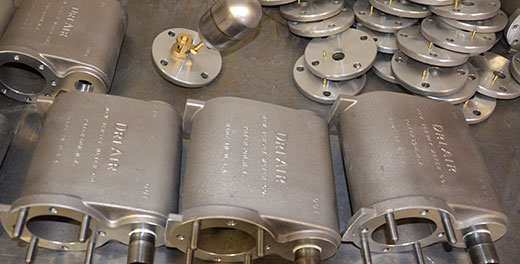

(Photo source: Net) Light weight aluminum spreading is an approach for creating high tolerance and high quality components by putting molten aluminum right into a specifically developed and precision engineered die, mold and mildew, or form. It is a reliable process for the production of complicated, elaborate, comprehensive parts that specifically match the requirements of the initial layout.

10 Easy Facts About Aluminum Castings Company Explained

This specific procedure is one of several methods utilized to produce aluminum castings, each of which is used for the development of certain sorts of components - Aluminum Castings Company. A variant in the spreading processes is the type of mold, which can be permanently constructed from steel or temporarily constructed from a non-metallic material

In order to discuss the aluminum spreading process, it is essential to analyze each of the various distinct techniques and exactly how they are utilized since there isn't simply one process. There are manufacturers that specialize in one or numerous methods, lots of manufacturers offer customers an option as to which procedure they would choose.

Aluminum Castings Company - An Overview

From the smallest electrical element considering less than a gram to transmission cases and clutch real estates for vehicles, casting creates each component specifically to the needs of the layout, perfectly with little requirement for finishing. The arrival of aluminum spreading has offered designers the opportunity to create any kind of sort of configuration with the guarantee that the component will certainly carry out up to expectations.

Computerization has actually enhanced the pressure to be capable of promptly shipments to satisfy consumer demands (https://sitereport.netcraft.com/?url=https://aluminumcastingscorp.com). As the demand for increased efficiency and performance grows, light weight aluminum die casting has actually been greater than qualified of conference and exceeding what has actually come to be required. Parts, elements, and workpieces are produced at a high rate of speed that is quicker than any type of other sort of alloy

6 Simple Techniques For Aluminum Castings Company

Aluminum items are lightweight yet have the toughness of steel. This factor contributes to their endurance and life expectations, an essential factor for 21st Century items. (Photo source: Internet) Though light weight aluminum spreadings are incredibly strong and lightweight, they have a really positive appearance and visual value. There are a number of uses for light weight aluminum casting that do not need them to be seen or have a pleasurable appearance.

Every sector is looking for means and techniques to lower expenses however generate high quality items. The inexpensive of the aluminum spreading procedure is a major consider why firms are selecting it for product advancement. Much of the expense financial savings is because of the rate of production and the elimination of the need to finish completed items.

When aluminum castings are subjected to the air, their surface becomes oxidized, which is a here characteristic of the metal. This one element is the reason that light weight aluminum spreadings have longevity and dependability.

Some Ideas on Aluminum Castings Company You Need To Know

This write-up has all the information you require to find out about light weight aluminum spreading (Aluminum Sand Castings). You will learn more about subjects such as: What is light weight aluminum spreading? Aluminum spreading refines Light weight aluminum alloys Advantages of aluminum casting And a lot more Light weight aluminum casting is the procedure of putting molten light weight aluminum into specifically crafted passes away, mold and mildews, or types to manufacture get rid of high accuracy and premium quality

However, it deserves keeping in mind that the first development, CNC machining, and tooling of these long lasting molds is labor-intensive and calls for upfront financial investment, which must be taken into consideration when examining general manufacturing expenses versus various other casting methods such as sand casting or low-pressure spreading. In spite of this, the long-lasting benefitssuch as lowered per-unit cost, outstanding component consistency, and shorter lead timesoften outweigh the preliminary configuration expenditures for mid- to massive light weight aluminum spreading projects.

The mold and mildew is diligently engineered to match the exact geometric shape and casting tolerance needed for the partoften split into 2 or more fifty percents (often called die halves). Throughout steel spreading, these halves are clamped firmly with each other to avoid the introduction of air, pollutants, or inclusions, making certain a dense and defect-free structure.